Along Mark Josephson, Co-Founder and Director CORIS Life Science Monitoring

U.S. Department of Agriculture estimates 30-40% of food is wasted each yearWhile this waste can be attributed to multiple sectors within the food supply chain – from retailers over-ordering to consumers throwing away their excess – it is an incentive for food manufacturers to focus on their own operations. It is

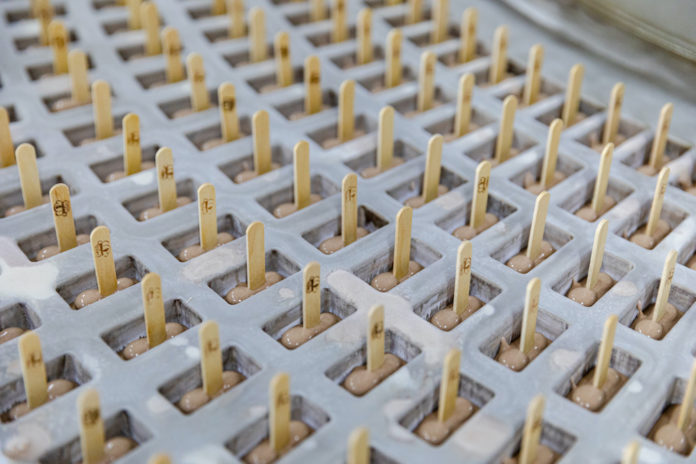

For frozen food manufacturers, the products sold are aimed at minimizing food waste at the consumer level. Frozen food can stay fresh longer.And in this regard, research shows they have succeeded. british food journal, Frozen food reduces food waste by 47% At home than refrigerated food at room temperature.

The nature of the product reduces waste, but this waste reduction that is part of the frozen food manufacturing process is just as important. After all, product loss comes at a high price. Especially if you are doing food production in small quantities.

What Product Loss Means for Small Batch Food Producers

Suppose you are an ice cream maker with $90,000 worth of product in just one of your facility’s freezers. Over the weekend, the freezer malfunctioned and staff came to the facility on Monday to discover that all the ice cream in the freezer had melted and had to be discarded.

For large manufacturers, this scenario is problematic both from a cost perspective and the manual effort required to scrap and replace products. However, capital reserves and production capacity are quickly restored and we are able to fulfill customer orders with only minor delays.

Low volume manufacturers face a much bigger problem. It’s a problem that could actually put you out of business. When these small food manufacturing operations are set back by a freezer failure, it can take two to three weeks to fill an open customer order due to limited production capacity. To maintain their business, manufacturers’ customers need to find alternative suppliers. This means that we may lose immediate orders and lose customers to these other suppliers indefinitely. Some people have a hard time getting back on their feet, while others never recover at all.

Product loss can be particularly costly for low-volume manufacturers, but it is also worth noting the importance of reducing food waste from a sustainability perspective. Less food is wasted in the frozen food manufacturing process, less energy is wasted and greenhouse gas emissions are minimized.In addition, data show that consumers are willing to pay 30-40% more sustainably produced goods.

How 24/7 Temperature Monitoring Helps Minimize Losses

Storage freezers are an integral part of the frozen food manufacturing process, storing products after they are manufactured and before they reach their next destination in the supply chain (grocery store, restaurant, or another retailer). To do.

As a mechanical system, it doesn’t matter If One of these freezers breaks down, whenCommercial and industrial grade freezers have a lifespan of about 10 years or more, but premature system failure can be caused by a variety of factors, from lack of proper maintenance (such as dirty compressor coils and frost build-up) to improper use. may occur. (e.g. overloading the freezer with food).

Given that freezer failures can occur at any time of the day, it is important not only to monitor these systems regularly, but to monitor them continuously. Especially if there is a power outage or internet outage. This level of comprehensive oversight ensures that your freezer (and frozen food manufacturing process) is built to weather the storm.

Think of 24/7 temperature monitoring as your food safety net. Aggressive investment means reducing future product losses.

Mark Josephson is CORIS Life Science Monitoringa company that provides sensor-based temperature and energy monitoring solutions.

Mark Josephson is CORIS Life Science Monitoringa company that provides sensor-based temperature and energy monitoring solutions.